- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

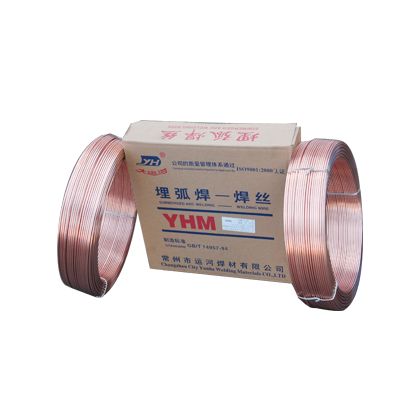

ER308 Stainless Steel

GUJIN® as the professional manufacturer, we would like to provide you ER308 Stainless Steel. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.

Send Inquiry

GUJIN® as a professional ER308 Stainless Steel manufacturer. Submerged arc welding wire,AWS A5.9 ER308, using with Stainless steel Submerged arc welding flux SJ-601 Deposited metal has good mechanical properties and intergranular corrosion resistance. Good cracking resistance.

Uses:

Stainless steel welding wire GJ-308 is used together with submerged arc flux SJ-601 to weld 18Cr-8Ni and 20Cr-10Ni austenitic stainless steel with similar composition. It is a common welding material for 08Cr19Ni9 (304) stainless steel. The products are widely used in mechanical industries such as offshore oil, natural gas, pressure vessels, chemicals, transportation, mining, and water conservancy.

Notes:

1. Recommendation temperature on welding bead around 150°C.

2. Operator should strictly follow with operation specification. Amps and speed of welding should be maintained in order to avoid metal deformation by overheating.

3.2 hour drying process is required (300-350°C) before use.

The above suggestions are for reference purpose. Evaluate and determine the situation of the scene before startingthe wielding process.

Reference Current(DC+)

|

Diameter |

2.5mm |

3.2mm |

4.0mm |

5.0mm |

|

Welding Current(Amps) |

400-500 |

450-550 |

500-600 |

550-650 |

|

Mechanical Properties (Using with Flux SJ-601) |

||

|

Yield Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

|

Guarantee value |

≥520 |

≥30 |

|

General result |

590 |

42 |

Welding Positions:

|

Product Name |

Dia (mm)

|

Chemical composition of welding wire |

|||||||

|

C |

Mn |

Si |

P |

S |

Cr |

Ni |

Cu |

||

|

GJ-307 |

1.6-5.0 |

0.08 |

1.0-2.5 |

0.3-0.65 |

0.03 |

0.03 |

19.5-22.0 |

9.0-11.0 |

0.75 |