- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

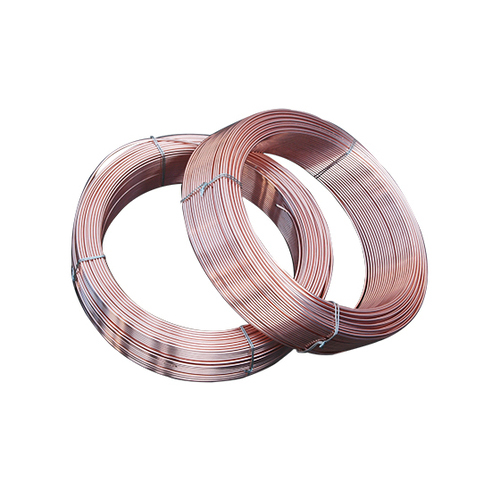

Submerged Arc Welding Wire EM13K

As the professional manufacture, GUJIN® would like to provide you Submerged Arc Welding Wire EM13K. For Submerged arc welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Submerged arc welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Submerged arc welding wire have characteristic design & practical performance & competitive price, for more information on the Submerged arc welding wire, please feel free to contact us.

Send Inquiry

GUJIN® is one of the famous China Submerged Arc Welding Wire EM13K manufacturers and suppliers. Submerged arc welding wire,GJ-H10MnSi(EM13K) is a kind of welding wire with appropriate manganese and silicon content. It matches with low-manganese and low-silicon type welding flux. It is not sensitive to the rust on the base metal. It has excellent bead molding, excellent slag detachability. The wire can be applied single or dual feeding with AC/DC.

Uses:

Submerged arc welding wire GJ-H10MnSi(EM13K)can be applied both for high-speed welding steel plate of tensile strength 420N/mm² and filling welding. It is widely used for welding boiler, pressure vessel, bridge, ship etc.

Notes:

1. Shielding gas: Adopt pure Argon gas. Recommendation flow rate: 9-14L/min (AMP 100-200A), 14-18L/min (AMP 200-300A)

2. Tungsten extension: 3-5mm, Arc length: 1-3mm.

3.Wind speed limited: <1.0m/s.

Argon gas shielding on back side of welding part will get better welding result.

4.Mechanic property and metal anti-cracking ability of the welded metal relative by energy pass value on the wire.

5. The welding should be operated in clean surface without rust, moist, oil contamination and dust.The above suggestionsare for reference purpose. Evaluate and determine the situation of the scene before starting the wielding process.

Reference Current(DC+)

Diameter:2.5mm、3.2mm、4.0mm、5.0mm

Welding Positions:

|

Product Name |

Standard and steel grade |

Dia (mm)

|

Chemical composition of welding wire |

|||||||||

|

GB |

AWS |

DIN/BS |

C |

Mn |

Si |

P |

S |

Cr |

Ni |

Cu |

||

|

GJ-H10MnSi |

H10MnSi |

EM13K |

- |

2.0-5.0 |

≤0.14 |

0.8-1.10 |

0.6-0.9 |

≤0.035 |

≤0.035 |

≤0.20 |

≤0.30 |

≤0.35 |

|

Typical Mechanical Properties of The Deposited Metal (Using with Flux SJ-101) |

||||

|

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

Elongation (%) |

Impact test |

|

|

Temperature (℃) |

Impact Energy (J) |

|||

|

≥420 |

≥500 |

≥22 |

-20 |

145 |